Glass-to-metal bonding with reduction (or even elimination) of glue at the interface

The aim of this project is to improve glass/metal bonding processes by reducing the use of bonding resins, particularly for use in the space industry. It proposes either to reduce the quantity of adhesive by plasma treatment of the surfaces to be bonded, or to consider a glue-free solution.

Reducing adhesive resins

As part of an eco-design and eco-development approach to optronic systems, there is a real advantage in trying to reduce integration and manufacturing times for parts requiring glass/metal bonding. With this in mind, the project is working on reducing the use of bonding resins, for outgassing reasons, through appropriate surface treatments on both metal and ceramic parts.

Adhesive and molecular bonding

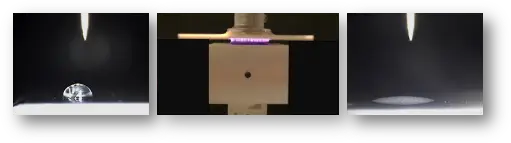

The aim of this project is to use atmospheric-pressure plasma processes, which are lighter than low-pressure processes, to produce surface treatments for adhesive and molecular bonding. Adhesive anchorage in surface asperities, wettability and the ability of adhesive and substrate to form common molecules are all necessary for successful adhesive bonding. Molecular adhesion involves bringing together two surfaces, either hydrophilic or hydrophobic, that are sufficiently rough and clean for bonding to take place via intermolecular forces, and making covalent bonds by applying a heat treatment.

Academic laboratories

GREMI – CNRS / University of Orléans

ICMN - CNRS / University of Orléans

Industrial partner

CILAS, orléans (45)

Funding

168k€ over 3 years

from regional funds (ARD CVL)

Recruitment

1 post-doc

over two years

Contact

François Faubert francois.faubert@univ-orleans.fr